Navigating the New Era of Sustainable Printing: CNCINK's Solutions for a Low-Carbon Future

Release time:

2025-06-05

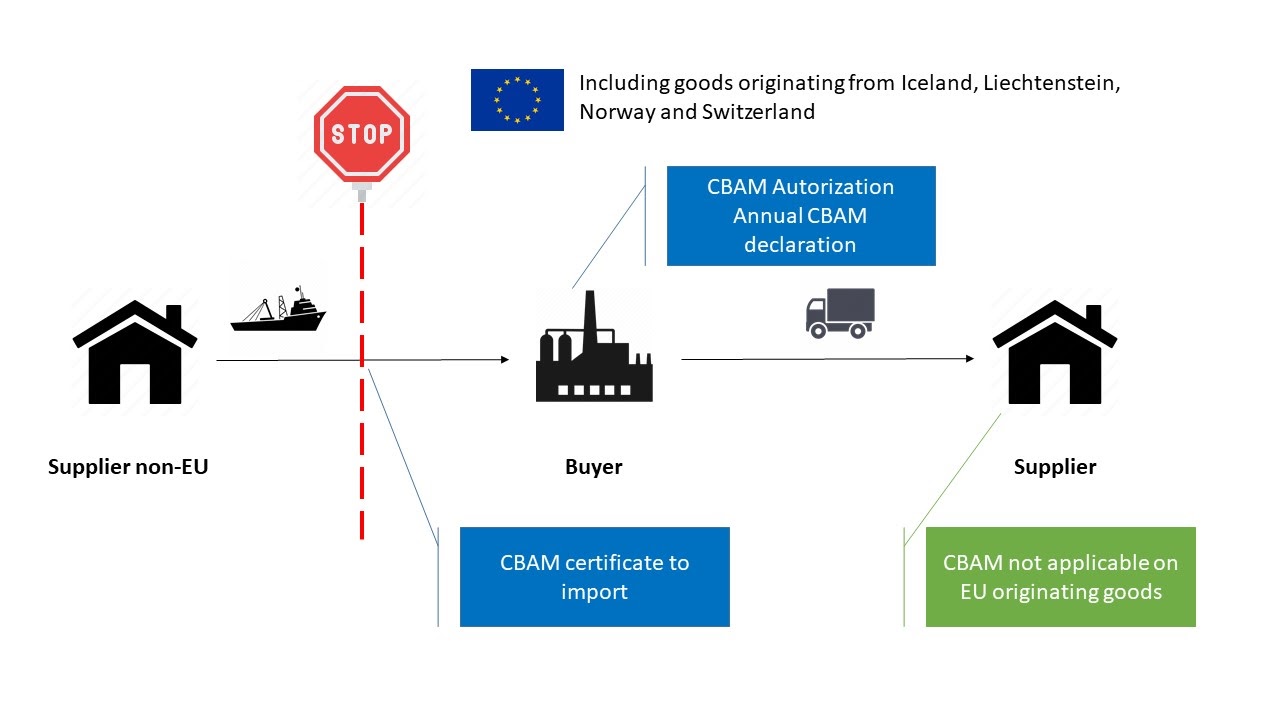

The global printing industry faces mounting pressure to reduce its environmental footprint amid tightening regulations like the EU’s Carbon Border Adjustment Mechanism (CBAM), which imposes 12% tariffs on non-low-carbon ink users. Traditional inks, plagued by high VOC emissions, energy-intensive production, and compatibility issues with diverse substrates, are no longer viable for modern, sustainability-driven markets. By integrating CNCINK’s innovative inks, businesses can transform regulatory compliance into a competitive edge. The company’s blend of bio-based formulations, energy-efficient technologies, and circular systems exemplifies how industry leaders can harmonize profitability with planetary health.

1. The Hidden Costs of Traditional Printer Inks

While printer inks have revolutionized digital printing, their environmental and operational drawbacks are becoming untenable. Conventional solvent-based inks, for instance, emit volatile organic compounds (VOCs) that contribute to air pollution and health risks for workers. Water-based inks, though less harmful, often lack adhesion on non-porous substrates like plastics, forcing manufacturers to use energy-intensive primers. Moreover, frequent nozzle clogging from pigment settling (a common issue in UV-curable inks) disrupts production cycles and increases waste. These inefficiencies, coupled with the rising cost of raw materials like petroleum-based resins, highlight an urgent need for innovation.

2. The Rising Tide of Environmental Regulations

The EU Carbon Border Adjustment Mechanism (CBAM), effective 2026, marks a pivotal shift. By imposing a 12% tariff on imports using non-low-carbon inks, the EU aims to decarbonize global supply chains. For example, a Chinese electronics brand using traditional solvent inks now faces an additional €1.2 million annual tariff for exporting to the EU—a cost that threatens profit margins and market competitiveness.

Beyond the EU, China's "14th Five-Year Plan" mandates a 30% reduction in VOC emissions from printing by 2025, incentivizing manufacturers to adopt eco-friendly alternatives. Meanwhile, the U.S. EPA's revised Printing and Imaging Equipment Standards require ink manufacturers to disclose lifecycle carbon footprints, pushing the industry toward transparency.

3. Corporate Dilemmas: Balancing Compliance and Profitability

Businesses are caught in a paradox:

- Cost Pressures: Transitioning to compliant inks requires R&D investments and supply chain overhauls. For SMEs, this is particularly daunting.

- Consumer Demand: 68% of global consumers prioritize sustainability, yet only 22% are willing to pay a premium for eco-certified products.

- Operational Risks: Non-compliance risks market exclusion. A 2024 study by GreenPrint Alliance found that 41% of European retailers now reject shipments violating CBAM.

4. CNCINK's Sustainable Printing Solutions

To address these challenges, CNCINK offers a suite of innovative, low-carbon digital printing solutions designed to reduce environmental impact without compromising performance:

Water-Based Inks

- Eco-Friendly Composition: Made with 60% bio-based resins (soybean, castor oil) and zero petroleum derivatives, our water-based inks reduce VOC emissions by 75% and comply with EU REACH standards.

- Versatility: Ideal for food packaging, pharmaceuticals, and children's toys, these inks adhere to hygienic standards and eliminate the need for toxic solvents.

- Case Study: A European cosmetics brand reduced water consumption by 40% and achieved OEKO-TEX® certification using our water-based inks for label printing.

UV Inks

- Low Energy Consumption: UV inks cure instantly under UV light, slashing drying time by 60% and energy use by 35%.

- High Durability: Resistant to abrasion and UV fading, these inks are perfect for outdoor signage and automotive decals.

- Application Highlight: A packaging company in Southeast Asia cut production costs by 22% by switching to CNCINK's UV inks for rigid plastic containers.

DTF (Direct-to-Film) Inks

- Waste Reduction: DTF inks eliminate the need for pre-treated fabrics and excess water, reducing water waste by 50% in textile printing.

- Flexibility: Compatible with polyester, cotton, and blends, these inks enable vibrant, durable prints for custom apparel and promotional items.

- Client Success: A fast-fashion retailer in Turkey reduced lead times by 30% and achieved zero-waste certification using CNCINK's DTF inks for on-demand T-shirt printing.

Textile Pigment Inks

- Eco-Conscious Dyeing: Our textile pigment inks replace traditional dye baths, cutting water usage by 70% and eliminating heavy metal contaminants.

- Soft Hand Feel: Designed for soft-touch fabrics, these inks maintain fabric flexibility while delivering rich colors.

- Industry Impact: A sportswear manufacturer in Vietnam met strict RSL (Restricted Substances List) requirements using our pigment inks, securing contracts with Nike and Adidas.

UV-DTF Inks

- Hybrid Innovation: Combining UV curing with DTF transfer technology, these inks enable high-resolution prints on complex surfaces (e.g., electronics, ceramics).

- Reduced Energy Use: UV-DTF inks cure at lower temperatures (60–80°C vs. 150°C for traditional UV), slashing energy costs by 25%.

- Case Study: A medical device company used UV-DTF inks to print biocompatible labels on surgical tools, reducing production energy by 30% and achieving FDA compliance.

Tailor-Made Solutions

- Custom Formulations: Adjust pigment concentration, viscosity, and curing parameters for niche applications (e.g., flexible electronics, 3D-printed ceramics).

- Closed-Loop Systems: Partner with CNCINK to implement ink recycling programs, recovering 85% of unused ink for reuse.

5. The Path Forward: Collaboration and Innovation

- Governments and corporations must synergize:

- Policy Incentives: Expand tax breaks for R&D in biodegradable inks (e.g., China's 15% VAT reduction for green technologies).

- Industry Alliances: Establish cross-border recycling networks, akin to the EU's InkCycle Initiative, to standardize waste management.

- Consumer Education: Leverage blockchain for ink traceability, empowering brands like CNCINK to showcase carbon-neutral certifications at point-of-sale.

The era of disposable, high-carbon inks is over. By integrating CNCINK's water-based, UV, DTF, and textile pigment inks, businesses can turn regulatory hurdles into competitive advantages—proving that profitability and planetary health are not mutually exclusive.

CNCINK: Pioneering Inks for a Greener Tomorrow

Contact us to schedule a sustainability audit and discover how our tailored solutions can transform your printing operations.

Sources: Industry reports from GreenPrint Alliance, EU CBAM documentation, and CNCINK R&D whitepapers.

Expanded Sections & Technical Insights

Technical Specifications of CNCINK's UV-DTF Inks

Parameter | Specification | Environmental Benefit |

Curing Temperature | 60–80°C | 40% energy savings vs. traditional UV |

VOC Emissions | ≤5 g/L | Compliant with EU REACH |

Adhesion Compatibility | Polyester, cotton, metal, ceramics | Compliant with EU REACH |

Print Resolution | 1200 dpi | Reduces ink waste by 20% |

Client Testimonials

1. "Switching to CNCINK's water-based inks cut our carbon footprint by 35% and improved print quality for food-safe packaging."

— Quality Control Manager, EU Food Packaging Firm

2. "DTF inks enabled us to transition to 100% digital workflows, eliminating chemical waste from screen printing."

— Sustainability Director, Fast-Fashion Brand

Previous

Previous:

Recommended news